LESSONS FROM PROS

Published 12:00 am Friday, August 22, 2003

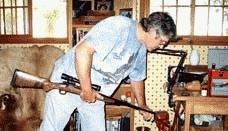

- CUSTOM EYE: Custom gun builder Jim Rector examines a rifle at his home. (Observer photos/DICK MASON).

By Dick Mason

Observer Staff Writer

When gunsmith Jim Rector is not restoring history he is making it.

Rector, who lives north of La Grande, brings the past alive by repairing and restoring guns, some of which are more than a century old. They include an 1886 lever-action Winchester rifle, which Rector is in the process of restoring.

andamp;quot;It is amazing what (gunsmiths) did a hundred years ago with no digital readouts and only crude tools,” Rector said.

Rector’s reverence for gun makers of the past doesn’t distract him from the present. He is a cutting-edge gunsmith, one whose work has earned him national recognition.

For example, a year ago he completed a custom .270-caliber Winchester Short Magnum rifle. The gun is believed to be the first rifle ever chambered in this caliber, according to the September 2002 edition of Rifle magazine.

The striking rifle is one of many pieces of evidence indicating that Rector adheres to his motto, one posted in his shop which reveals his belief and personable nature:

Life is too short to hunt with an ugly gun

The quote is attributed to the late Texas gunsmith Maurice Ottmar. Rector never studied under Ottmar, but he has studied under other highly regarded gunsmiths. He credits Pete Grisel of Milton-Freewater, Bill Knechtel of Baker City and the late Kissey Kimball of Texas with playing important roles in developing his skills. The lessons Rector has learned from them are applied daily. They have allowed him to become one of the most versatile gunsmiths in the region.

Many gunsmiths have specialties, but few are able to do all of the things that go into the making of a gun, including wood and metal work and engraving.

Ideally, Rector would like to spend all of his time building custom guns. However, this is not a realistic dream.

andamp;quot;People are always breaking things. Someone has got to fix them,” Rector said.

He also realizes that repairing guns is a way of building a good clientele. Some of those he has repaired guns for end up asking him later to make them a custom gun.

Rector said that he and other gunsmiths are reluctant to repair cheap guns because it often costs more to repair them than to replace them. This is particularly true of .22-caliber rifles, which Rector prefers not to repair.

andamp;quot;Unless the gun has sentimental value I will usually offer to buy it for parts,” said Rector, who has worked as a gunsmith for 13 years.

Molding metal and wood

To be a gunsmith is to be a craftsman of metal and wood. Gunsmiths always do their metal work first and then mold the wood around it. He shapes the metal and then contours the wood to the metal.

andamp;quot;You shape it to the metal and it all flows together,” Rector said.

English walnut is the wood of choice for many gunsmiths because of its appearance and malleability. The drawback is that English walnut is expensive.

Rector’s second choice is black walnut, which is less expensive but also has a good appearance. He gets some of his black walnut from The Dalles. He presently has two stock blanks of black walnut that came from the same tree in The Dalles and were cut side by side. Rector is keeping them in case he gets a request for custom guns for two people such as a father and son or a husband and wife. He wants to be able to make a set of guns with identical wood.

andamp;quot;I won’t sell one stock. I’m saving them for someone who wants a matching set,” Rector said.

The final step in creating a gun is checkering the wood. This is the process of engraving a checkered pattern in the gun stock. It is a painstaking process, one that takes 20 hours.

Guns that are mass produced have checkered patterns pressed onto the wood. Custom guns have hand checkering that is more eloquent and sharply defined.

Designing the checkered pattern is often more difficult than the actual process of hand checkering, Rector said.

Although Rector has great appreciation for how guns were made in the past, he enjoys having the advantage of using high- tech equipment for the guns he makes. It can be used to enhance the custom look of a gun.

andamp;quot;I am very grateful for technology. The tools make it so much easier. You still have craftsmanship to go along with it,” Rector said.

Rector, who was a welder before becoming a gunsmith, makes four to five guns a year. He gets attached to them but not too much so.

andamp;quot;You can’t get married to them. You have to sell them,” Rector said.

He said that building a gun can be a tedious process because so many steps are involved.

The work is worth it when he sees the look on the faces of customers.

andamp;quot;The anticipation of (the response of the customer) is one of the best parts,” Rector said.