BOISE CASCADE ADDS SECOND SHIFT AT STUD MILL

Published 12:00 am Wednesday, June 20, 2001

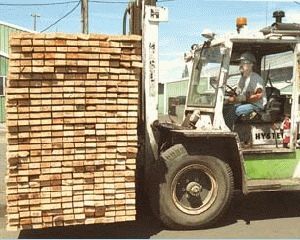

- AT WORK IN ELGIN: Don Nitzel moves a load of 2-by-4s to the planer at Boise Cascade's Elgin sawmill Monday. Nitzel is among workers from closed Boise Cascade mills in Idaho who are now working at the Elgin mill (The Observer/PHIL BULLOCK).

By Ray Linker

Observer Staff Writer

ELGIN Monday will be a red-letter day in town.

It marks the startup of another shift at Elgins Boise Cascade stud mill and the addition of 21 jobs.

This is really good news for Northeast Oregon, said Bruce Cartmel, Boise Cascades regional manager in La Grande.

This is a mill complex that was facing total closure after an extensive fire ravaged the plywood plant May 25, 1999, knocking out two veneer dryers and doing extensive structural damage. Boise Cascade also considered closing the adjacent stud mill plant.

Instead, the company decided to rebuild the burned-out section and replace the machinery at a cost of about $14 million. It re-opened about six months later.

Putting on another shift is fantastic, said Lewis Bly, manager of the stud mill section of the Elgin operation.

The swing shift, bringing the total Elgin complex employees to 330, will work from 3:30 p.m. to 11:30 p.m., said David Salmon, the companys regional human resources manager.

With the startup, the stud mill, which turns out a premier 2-by-4 as a main product, will have approximately 130 employees. The plywood plant employs about 200.

The new shift and the boost in the Elgin economy comes at the expense of cutbacks by Boise in its operation at two Idaho plants. In what the company called a reconfiguration, plywood and lumber operations at Emmett, Idaho, and a sawmill at Cascade, Idaho, were closed, eliminating about 375 jobs.

The new Elgin employees are from the Idaho mills, Salmon said.

Its too bad the Idaho mills had to close, but this will be a boost to the Elgin economy, Salmon said. He said the Idaho closures came about because of a lack of a reliable timber supply from Idahos federal forests.

Bly, who has been with Boise Cascade for 23 years, was once a millwright at Cascade, which is between McCall and Boise. Hes been in Elgin for five years and did an 18-month stint at Horseshoe Bend near Boise.

We have a hard-working, experienced crew already here, and now its a plus to bring in these other, also experienced workers, from Idaho, to complement them, Bly said.

Its important for the community to know that our people are very knowledgeable about the stud business, Bly said.

The additional shift has little to do with market conditions, Salmon said. But he did say there are signs of improving prices for lumber and other products in a market that has been flat for some time.

Bly said most of the people hired from Idaho have been in Elgin since June 11, getting settled in their homes and receiving training on machinery in the Elgin plant.

They are finding housing without much of a problem. Some are renting, others buying. Some employees coming from Idaho are nearing retirement and will keep their Idaho homes, planning to go back there when they retire.

The influx of new people, some with families, will be good for the local economy and the school system, Salmon said.

The addition of the new shift is not something Boise Cascade has approached lightly or on a temporary basis, Salmon said.

Adding this shift is a long-term deal. We wouldnt be doing a start-up of another shift otherwise. We wouldnt place workers here for a short-term effort.

While we cant predict the future and cant promise (job security), were making a long-term commitment, Salmon said.

With the renovations following the fire, the complexs equipment is pretty well up to date, although theres always room for improvement, said Bly.

One part of the Elgin plant operation now, said Salmon, involves drying lumber produced at the

La Grande site. With the increase in natural gas prices, its cheaper to truck the lumber to Elgin, dry it in a hog-fuel-fed dryer and ship it back to La Grande.